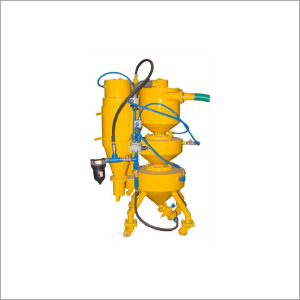

Cookware Blasting Machine

Price 1 INR/ Kilograms

Cookware Blasting Machine Specification

- Noise Level

- 80 dB

- Table Size

- 600 mm diameter

- Spindle Speed

- Fixed

- Motor Power

- 7.5 kW

- Frequency

- 50 Hz

- Diameter

- Range up to 600 mm

- Condition

- New

- Machine Type

- Rotary Table Blasting

- Features

- High Efficiency, Durable Construction, Uniform Blasting, Enclosed Cabinet

- Product Type

- Cookware Blasting Machine

- Material

- Mild Steel

- Computerized

- Yes

- Automatic Grade

- Automatic

- CNC Or Not

- No

- Control System

- PLC Control

- Voltage

- 380V

- Power

- 7.5 kW

- Power Source

- Electric

- Weight (kg)

- 1500 kg

- Dimension (L*W*H)

- 2200 x 1450 x 1900 mm

- Color

- Blue & Grey

- Usage & Applications

- Cookware Surface Preparation, Cleaning, Finishing

Cookware Blasting Machine Trade Information

- Minimum Order Quantity

- 1 Kilograms

- Supply Ability

- 500 Kilograms Per Day

- Delivery Time

- 1 Week

About Cookware Blasting Machine

We are a leading manufacturer, exporter and supplier of optimum quality Cookware Blasting Machine. Our offered machine is basically used for removing oxide layer from the surface and facilitate proper adhesion of PTFE coating. With high accuracy and easy operation, this machine is extensively demanded in automobile industry. This machine is manufactured with the help of cutting-edge technology by making use of optimum grade components under the visionary guidance of our skilled team of experts at our well-equipped production unit. Moreover, this Cookware Blasting Machine is available in different specifications to meet the specific requirements of our patrons.

Features:

-

Sturdy construction

-

No maintenance

-

User friendly design

-

Impeccable performance

Precision Cleaning and Finishing

This machine automates the blasting process for cookware, ensuring thorough surface preparation with consistent, high-quality results. Its rotary table design accommodates items up to 600 mm in diameter, making it versatile for various cookware types. The advanced PLC control system streamlines settings and operation, allowing users to achieve precise and uniform cleaning or finishing on every batch.

Advanced Construction for Reliability

Built from mild steel and finished in blue and grey, the machine boasts exceptional durability. The enclosed cabinet design not only enhances operator safety but also reduces noise emission to 80 dB or less. The robust 7.5 kW motor and fixed spindle speed provide reliable performance even during continuous operation, ensuring productivity in demanding industrial environments.

FAQs of Cookware Blasting Machine:

Q: How does the Cookware Blasting Machine enhance cookware surface preparation?

A: The machine automates the surface preparation by using a rotary table blasting method, which ensures even cleaning and finishing on every cookware piece. Its uniform blasting feature improves adhesion for coatings and maintains consistent quality.Q: What materials can be processed with this machine?

A: This blasting machine is suitable for cookware items made from various metals, accommodating pieces up to 600 mm in diameter. It is especially effective for items requiring thorough surface cleaning and preparation prior to further finishing processes.Q: When is it advisable to use this blasting machine in cookware production?

A: It should be used during the initial surface treatment phase, before any coating or finishing application, to remove impurities, old coatings, and prepare the surface for optimal adhesion and appearance.Q: Where can this machine be installed, and what are its space requirements?

A: The machine is designed for industrial settings like factories or workshops. With dimensions of 2200 x 1450 x 1900 mm and a weight of 1500 kg, it requires adequate floor space and a stable power supply (380V, 50 Hz).Q: What is the process used by the machine to clean cookware items?

A: The machine utilizes a rotary table blasting process under PLC control. Cookware items are placed on the table, and abrasive media is blasted at fixed spindle speeds, ensuring every surface is uniformly treated within the enclosed cabinet.Q: How is the machine operated and controlled?

A: Operation is streamlined through a computerized PLC control system, allowing users to set the required parameters and monitor the process. The automatic grade ensures minimal manual intervention, boosting productivity and safety.Q: What are the main benefits of utilizing this cookware blasting machine?

A: Key benefits include high efficiency, uniform results, durable construction, and reduced operational noise. It boosts productivity by automating cleaning and finishing, delivering consistently superior surface quality, and improving the longevity of subsequent coatings.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Special Purpose Blasting Machines Category

Swing Table Blasting Machine

Price 1 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Condition : New

Weight (kg) : 1200 kg (approx.)

Machine Type : Surface Cleaning

Power : 5 HP

Tumblast Shot Blasting Machines

Price 1 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Condition : New

Weight (kg) : 2200 7000 kg (depending on model)

Machine Type : Surface Finishing Equipment

Power : 10 HP 35 HP (varies by model)

Vacuum Blasting Machine

Price 1 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Condition : New

Weight (kg) : Approximately 280 kg

Machine Type : Portable Vacuum Blaster

Power : 7.5 kW

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS