Tumblast Shot Blasting Machines

Price 1 INR/ Kilograms

Tumblast Shot Blasting Machines Specification

- Motor Power

- Standard 15 HP main blast wheel motor

- Frequency

- 50 Hz

- Noise Level

- 85 dB

- Machine Type

- Surface Finishing Equipment

- Condition

- New

- Product Type

- Tumblast Shot Blasting Machine

- Material

- Mild Steel

- Computerized

- No

- Automatic Grade

- Automatic

- CNC Or Not

- No

- Control System

- PLC Control Panel

- Voltage

- 380V / 415V

- Power

- 10 HP 35 HP (varies by model)

- Power Source

- Electric

- Weight (kg)

- 2200 7000 kg (depending on model)

- Dimension (L*W*H)

- Variable by model (e.g., 2200 x 1300 x 2600 mm)

- Capacity

- 300 kg 1000 kg per batch (model dependent)

- Color

- Blue / Customized

- Usage & Applications

- Deburring, desanding, descaling, and surface preparation of castings and forgings

Tumblast Shot Blasting Machines Trade Information

- Minimum Order Quantity

- 1 Kilograms

- Supply Ability

- 500 Kilograms Per Day

- Delivery Time

- 1 Week

About Tumblast Shot Blasting Machines

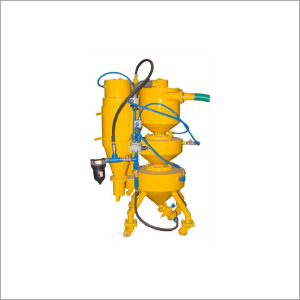

Tumblast Type Shot Blasting Machines

Tumblast table type machine is specially designed for the batch processing of metal parts. This machine allows for the efficient deburring, deflashing and peening of metal parts. Where cost of blasting is critical, mass production is the need, object is not going to be damaged due to tumbling as in the case of castings, forgings and other sturdy items.

This type of airless wheel type blasting machine offers ideal and most economic solution in terms of capital investment, processing cost, electricity, space etc.

Special Features

- Specially designed Blast Wheel for longer life and efficient blasting

- Automatic Loading and Unloading arrangement on request

- Fabric Bag Type or Cartridge Type Dust Collector as desired

- Machine to be PLC controlled if desired for precised / efficient control

Applications of Tumblast Machine

- Batch cleaning of metal parts

- Removal of rust, scale, heat scale and carbon build up from metals

- Extract residual sand and scale from castings, forgings

- Deflashing of metal parts

Versatile Surface Finishing Solutions

Designed for the demanding requirements of modern metal processing, Tumblast Shot Blasting Machines deliver consistent results for surface preparation, including deburring, desanding, and descaling. Their flexible batch capacity and robust construction cater to various industries while providing high efficiency and quality surface treatment.

Advanced Automation with PLC Controls

Each machine is equipped with a PLC control panel, enabling automated and reliable blasting cycles. This intelligent control system simplifies usage, enhances safety, and produces uniform finishes, reducing manual intervention and ensuring consistent performance regardless of operator skill level.

FAQs of Tumblast Shot Blasting Machines:

Q: How does the Tumblast Shot Blasting Machine operate for surface finishing?

A: The machine uses a tumbling barrel and high-speed blast wheels to propel abrasive media onto workpieces. This process removes scale, sand, and burrs, delivering thorough and uniform surface preparation for castings and forgings.Q: What materials and capacities can these machines handle?

A: Made from durable mild steel, the machines accommodate batch loads ranging from 300 kg to 1000 kg per cycle, suitable for a wide variety of castings, forgings, and other metal components requiring surface treatment.Q: When should I use a Tumblast Shot Blasting Machine in my manufacturing process?

A: Utilize the machine after casting, forging, or welding to efficiently remove unwanted residues, scales, or sand before painting, coating, or assembling your metal components.Q: Where are these machines commonly installed?

A: Tumblast Shot Blasting Machines are typically found in foundries, forging plants, metal fabrication shops, and facilities specializing in surface treatment and finishing processes across India.Q: What is the main control system used in these machines?

A: They feature an advanced PLC control panel, which automates the blasting process, improves precision, and offers straightforward operation through programmable settings.Q: What are the primary benefits of using a Tumblast Shot Blasting Machine?

A: These machines save time and labor by automating surface cleaning, enhance product quality through uniform treatment, and support high production efficiency while keeping noise below 85 dB for a safer work environment.Q: How does the automatic grade improve user experience compared to non-automatic machines?

A: Automatic operation ensures consistent results, minimizes manual errors, allows for repeatable processes, and reduces operational workload, making it ideal for high-volume industrial applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Special Purpose Blasting Machines Category

Cookware Blasting Machine

Price 1 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Weight (kg) : 1500 kg

Machine Type : Rotary Table Blasting

Computerized : Yes

Control System : PLC Control

Swing Table Blasting Machine

Price 1 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Weight (kg) : 1200 kg (approx.)

Machine Type : Surface Cleaning

Computerized : No

Control System : Other, Electric Panel

Vacuum Blasting Machine

Price 1 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Weight (kg) : Approximately 280 kg

Machine Type : Portable Vacuum Blaster

Computerized : No

Control System : Other, Pneumatic Control

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free