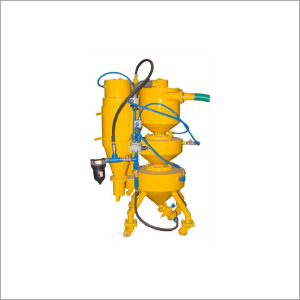

Vacuum Blasting Machine

Price 1 INR/ Kilograms

Vacuum Blasting Machine Specification

- Machine Type

- Portable Vacuum Blaster

- Dimension (L*W*H)

- 1180 x 820 x 1500 mm

- Motor Power

- 7.5 kW

- Frequency

- 50 Hz

- Diameter

- Blast hose: 32 mm

- Noise Level

- Below 85 dB

- Condition

- New

- Product Type

- Vacuum Blasting Machine

- Material

- Mild Steel

- Computerized

- No

- CNC Or Not

- No

- Control System

- Pneumatic Control

- Voltage

- 415 V

- Power

- 7.5 kW

- Power Source

- Electric

- Weight (kg)

- Approximately 280 kg

- Usage & Applications

- Surface cleaning, rust and scale removal, paint removal from metal, concrete, and similar surfaces

Vacuum Blasting Machine Trade Information

- Minimum Order Quantity

- 1 Kilograms

- Supply Ability

- 500 Kilograms Per Day

- Delivery Time

- 1 Week

About Vacuum Blasting Machine

Features:

-

Noise less operation

-

Power efficient

-

Rugged construction

-

Easy to operate

Vacuum Blast Equipment Specifications:

Restrictive environmental legislation and a greater awareness of health hazards were the main reasons for development of vacuum blasting equipment. The advantages of the equipment are not limited to preventing environmental and health problems, in many applications it is also a fully justified method of surface preparation on an economic basis. Disposal costs of hazardous waste is minimal by the use of recyclable abrasives, so the amount of abrasives used is much lower than compared with open-blasting. The equipment has many applications. Besides for construction and maintenance of ships, the equipment can also be used for the maintenance of bridges, machinery, power plants or for the renovation of concrete. steel, shipbuilding, offshore and (petro) chemical industries and also for maintenance purpose in the civil works sector such as cleaning bridges , tunnels and buildings etc.

The Synco Model : SPBV 08C-1 is a compact and versatile vacuum blasting machine which gives the user flexibility of cleaning components to a depth / height of about 5 mtrs from the machine position. The sturdy construction is designed for rough handling. This model is easy to move to the place of blasting due to its compact size where other machines find difficulty to reach such as submarine holds.

Advanced Surface Cleaning Technology

Combining blasting power with vacuum extraction, this portable machine streamlines surface treatment processes. Operators can achieve thorough cleaning while minimizing dust and airborne contaminants, supporting safer and cleaner working environments in industrial settings. Its efficient operation and low noise output make it suitable for use in areas where health and safety are priorities.

Reliable Design and Convenient Operation

Built with mild steel and engineered for electric operation, the Vacuum Blasting Machine ensures long-term durability and straightforward maintenance. Pneumatic controls provide responsive and precise management of blasting functions, while its compact dimensions allow easy mobility and setup at worksites requiring versatile surface preparation solutions.

FAQs of Vacuum Blasting Machine:

Q: How does the Vacuum Blasting Machine operate for surface cleaning tasks?

A: The Vacuum Blasting Machine uses a high-powered blast hose to propel abrasive media onto surfaces, efficiently removing rust, scale, or paint. Simultaneously, it deploys a vacuum system to collect spent abrasives and debris, keeping the workspace cleaner and safer.Q: What surfaces can be cleaned using this portable vacuum blaster?

A: This machine is designed for surface cleaning tasks on metal, concrete, and similar materials. It is suitable for removing paint, rust, and scale from various industrial surfaces, making it versatile for multiple applications.Q: When is vacuum blasting preferred over traditional methods?

A: Vacuum blasting is ideal when minimal dust and debris are required or where environmental controls are essential, such as indoor projects or sensitive manufacturing areas. Its low noise level also makes it suitable for settings with noise restrictions.Q: Where can this vacuum blasting machine be effectively used?

A: This portable unit can be deployed in manufacturing facilities, shipyards, construction sites, and industrial plants across India. Its design allows easy relocation for maintenance or renovation work wherever surface preparation is needed.Q: What is the process for operating and maintaining the machine?

A: Operators connect the 415 V power supply and set pneumatic controls for desired blasting intensity. After use, cleaning the vacuum hopper and inspecting the blast hose are recommended to maintain optimum performance and prolong equipment life.Q: How does the pneumatic control system enhance machine functionality?

A: The pneumatic control system enables precise adjustments to air flow and blasting power, resulting in consistent cleaning results and efficient media consumption, while also contributing to safer machine operation.Q: What are the benefits of using a vacuum blasting machine for industrial cleaning?

A: Key benefits include thorough surface cleaning, reduced airborne dust, improved worksite safety, low operational noise, and time savings due to its efficient debris collection and portability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Special Purpose Blasting Machines Category

Cookware Blasting Machine

Price 1 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Power Source : Electric

Frequency : 50 Hz

Computerized : Yes

Usage & Applications : Cookware Surface Preparation, Cleaning, Finishing

Swing Table Blasting Machine

Price 1 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Power Source : Electric

Frequency : 50 Hz

Computerized : No

Usage & Applications : Surface cleaning, rust removal, deburring, shot blasting of castings and forgings

Tumblast Shot Blasting Machines

Price 1 INR / Kilograms

Minimum Order Quantity : 1 Kilograms

Power Source : Electric

Frequency : 50 Hz

Computerized : No

Usage & Applications : Deburring, desanding, descaling, and surface preparation of castings and forgings

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free