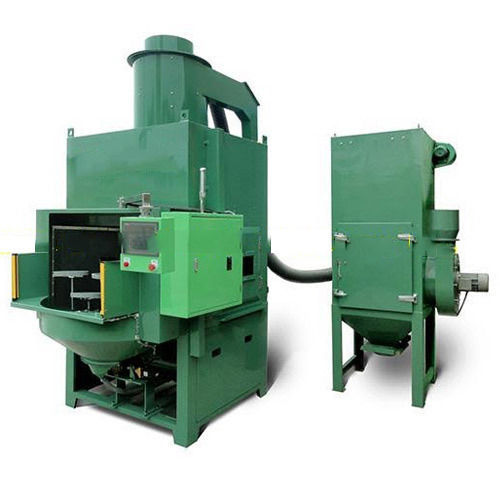

Indexing Table Type Deflashing Machine

Indexing Table Type Deflashing Machine Specification

- Current Range

- 3-5 A

- Phase

- Three Phase

- Application

- Deflashing of Molded Components

- Equipment Type

- Industrial Deflashing Machine

- Frequency

- 50 Hz

- Diameter

- 600 mm Table

- Power Consumption

- 2.5 kW

- Automation Grade

- Semi Automatic

- Power Source

- Electric

- Output Voltage

- 415 V

- Type

- Indexing Table Type Deflashing Machine

- Condition

- New

- Motor Type

- Servo Motor

- Material

- Mild Steel

- Power

- 3 HP

- Voltage

- 415 V

- Dimensions

- 1200 x 900 x 1500 mm

- Input Voltage

- 415 V AC

- Rated Current

- 5 A

- Rated Capacity

- 50-100 pieces/hour

About Indexing Table Type Deflashing Machine

The deflashing process is simply as below. Firstly, products are fixed on a gripper which locates outside a resolving door. The door turns exactly at 180 degree driven by motor and sends the products to designated position in the blasting room. Products will rotate themselves as driven by rotary motor. Meanwhile, 12 guns throws out nylon shots bumping into products. When deflashing time is up, the door automatically indexes out those finished products and at the same time indexes in products to be deflashed. It is quite an automatic circulation system.Customer can choose computer control or manual control. As for computer control, one press only can start the whole system and achieve continuous deflashing.

Callback

Advanced Table Indexing System

This machine comes with a precision gear motor and cam indexer, allowing for automated and repeatable positioning across 6, 8, or 12 stations. This improves cycle efficiency and optimizes throughput, making it suitable for diverse production volumes and component types.

Safety and User-Friendliness

Equipped with an interlocked guarding system and emergency stop feature, the machine ensures operator safety during operation. The intuitive touch screen HMI simplifies process control, enabling quick adjustments and easy operation, even for new users.

Efficient Deflashing Process

With options for rotary cutter or pneumatic tool deflashing, the machine delivers consistent removal of excess material. Optional air jet or blower cooling maintains component integrity and process stability. Designed for applications in industrial environments, it supports high-quality production output.

FAQs of Indexing Table Type Deflashing Machine:

Q: How does the Indexing Table Type Deflashing Machine operate?

A: The machine uses a PLC-based control system and a servo motor-powered cam indexer to advance the table to each station. Components are loaded manually and undergo deflashing at each position using either a rotary cutter or pneumatic tool, depending on the requirement.Q: What types of components can this deflashing machine process?

A: It is ideal for molded components requiring removal of flash, serving applications in various industries such as automotive, electrical, and consumer goods. The machine accommodates a table diameter of up to 600 mm and is adaptable for components of different shapes and sizes.Q: When is the cooling system used during operation?

A: The optional air jet or blower cooling systems are utilized when processing heat-sensitive materials or when continuous operation is required, ensuring component integrity and preventing thermal damage during the deflashing process.Q: Where is the Indexing Table Type Deflashing Machine typically installed?

A: It is installed in industrial manufacturing facilitiesespecially those requiring semi-automatic, high-throughput deflashing of molded parts. The machine can be integrated easily into existing production lines or used as a standalone solution.Q: What benefits does this machine provide over manual deflashing methods?

A: The automated indexing and deflashing system increases productivity, ensures consistent quality, reduces manual labor, and enhances operator safety with its interlocked guarding and emergency stop features. It also delivers lower noise levels (<75 dB(A)) and a cleaner working environment.Q: How is the operator panel designed for user ease?

A: The operator panel features a touch screen HMI, making it straightforward to set parameters, monitor machine status, and control the process. This minimizes training time and allows for quick troubleshooting and adjustments.Q: What are the power and air supply requirements for this equipment?

A: The machine operates on 415 V AC, requires a three-phase supply at 50 Hz, and consumes approximately 2.5 kW of power. If pneumatic tools are used, a compressed air supply of 6 bar is necessary for optimal performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Deflashing Machines Category

Tumble Batch Deflashing Machine

Material : Mild Steel (MS), Stainless Steel

Power Source : Electric

Type : Tumble Batch Deflashing Machine

Application : Rubber and plastic product deflashing

Motor Type : Other, Electric

Condition : New

Rotary Table type Deflashing Machine

Material : Highgrade Stainless Steel

Power Source : Electric

Type : Rotary Table type Deflashing Machine

Application : Rubber and Plastic Moulded Product Deflashing

Motor Type : Other, Induction Motor

Condition : New

Automatic Tunnel Type Continuous Deflashing Machine

Material : Mild Steel

Power Source : Electric

Type : Continuous

Application : Deflashing

Motor Type : Other, Induction Motor

Condition : New

Automatic Tumbling Belt Deflashing Machine

Material : Metal

Power Source : Electric

Type : Belt Tumbling Machine

Application : Deflashing of components

Motor Type : Other, Beltdriven motor

Condition : New

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free