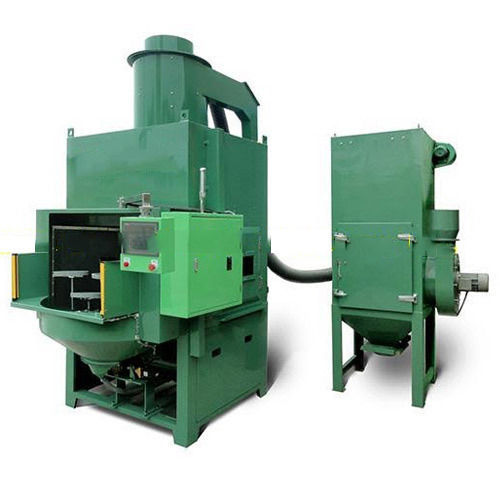

Rotary Table type Deflashing Machine

Rotary Table type Deflashing Machine Specification

- Current Range

- 6-8 A

- Power Source

- Electric

- Automation Grade

- Automatic

- Diameter

- Rotary Table: 800 mm

- Phase

- Three Phase

- Power Consumption

- 2.5 kWh

- Application

- Rubber and Plastic Moulded Product Deflashing

- Frequency

- 50 Hz

- Output Voltage

- 415 V

- Type

- Rotary Table type Deflashing Machine

- Condition

- New

- Motor Type

- Induction Motor

- Material

- High-grade Stainless Steel

- Power

- 2.5 kW

- Voltage

- 415 V

- Dimensions

- 1200 mm x 1000 mm x 1600 mm

- Input Voltage

- 415 V AC

- Rated Current

- 7 A

- Rated Capacity

- 50 kg per cycle

- Cleaning Time Per Batch

- 5 - 15 mins

- Environment

- Dust-Proof & Low-Vibration Design

- Speed

- Variable Table Speed up to 15 rpm

- Loading/Unloading

- Manual or Pneumatic Assistance

- Nozzle Type

- Adjustable High-Pressure Blast Nozzle

- Control Panel

- Digital Timer & Speed Control

- User Interface

- Push Button Type

- Air Supply

- Required for Pneumatic Model

- Safety Features

- Overload Protection & Emergency Stop

- Maintenance

- Low Maintenance Design

- Finishing

- Powder Coated Body

- Deflashing Media

- Plastic Pellets/Critical Media

- Noise Level

- < 70 dB

About Rotary Table type Deflashing Machine

This machine is ideal for deflashing parts with intricate areas, parts made with PA (adding 40% or more glass fiber), PPS, LCP, PBT, PET and other thermoset products like bakelite, BMC, SMC etc.

Callback

Efficient and Flexible Deflashing Process

This rotary table machine automates the deflashing of rubber and plastic moulded parts, achieving superior results with adjustable speeds and high-pressure blast nozzles. The system is designed for use in various factory settings, accommodating both manual and pneumatic loading, and allowing for precise control with a digital timer and variable speed adjustments.

Robust Safety and User-Friendly Features

Operator safety is at the forefront, with essential protections such as overload protection and an emergency stop function. The user interface is simple, employing intuitive push-button controls. Additionally, the machines durable, powder-coated construction and low-vibration design ensure longevity and a quieter workspace, maintaining noise levels below 70 dB.

FAQs of Rotary Table type Deflashing Machine:

Q: How does the rotary table type deflashing machine operate?

A: The machine works by rotating components on a table while an adjustable high-pressure blast nozzle removes flash using plastic pellets or similar media. The cycle settings, including timer and rotation speed, can be controlled via the digital panel, and parts can be loaded manually or with pneumatic assistance.Q: What types of products can be cleaned with this deflashing machine?

A: It is specially designed for deflashing rubber and plastic moulded components. The adjustable nozzle and media type make it suitable for a wide range of product geometries and sizes, offering flexibility in application.Q: When should pneumatic assistance for loading/unloading be used?

A: Pneumatic assistance is recommended for handling bulkier or heavier batches, or when productivity needs to be maximized. Manual loading is suitable for smaller volumes or delicate parts.Q: Where is the machine best installed in a production facility?

A: The machines compact, dust-proof, and low-vibration design allows it to be integrated into assembly lines or finishing areas within industrial plants, especially in settings where rubber and plastic components are processed.Q: What is the maintenance process for this machine?

A: Thanks to its low-maintenance, robust design and high-grade stainless-steel construction, routine care involves cleaning, occasional inspection of nozzles and blast media, and ensuring air supply lines (for pneumatic models) are clear and functional.Q: How does the digital timer and speed control benefit users?

A: The digital timer and variable speed control allow users to precisely set batch processing times (5-15 minutes) and adjust rotation speed up to 15 rpm, optimizing deflashing quality for different types of products and improving operational efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Deflashing Machines Category

Tumble Batch Deflashing Machine

Material : Mild Steel (MS), Stainless Steel

Power Source : Electric

Automation Grade : SemiAutomatic

Application : Rubber and plastic product deflashing

Motor Type : Other, Electric

Type : Tumble Batch Deflashing Machine

Indexing Table Type Deflashing Machine

Material : Mild Steel

Power Source : Electric

Automation Grade : Semi Automatic

Application : Deflashing of Molded Components

Motor Type : Other, Servo Motor

Type : Indexing Table Type Deflashing Machine

Automatic Tunnel Type Continuous Deflashing Machine

Material : Mild Steel

Power Source : Electric

Automation Grade : Automatic

Application : Deflashing

Motor Type : Other, Induction Motor

Type : Continuous

Automatic Tumbling Belt Deflashing Machine

Material : Metal

Power Source : Electric

Automation Grade : Automatic

Application : Deflashing of components

Motor Type : Other, Beltdriven motor

Type : Belt Tumbling Machine

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS