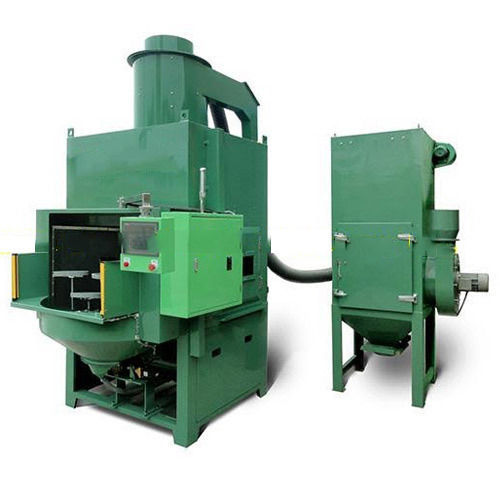

Tumble Batch Deflashing Machine

Tumble Batch Deflashing Machine Specification

- Frequency

- 50 Hz

- Current Range

- 3-5 A

- Application

- Rubber and plastic product deflashing

- Power Source

- Electric

- Power Consumption

- 2 kW

- Equipment Type

- Batch Deflashing Machine

- Output Voltage

- 415 V

- Automation Grade

- Semi-Automatic

- Phase

- Three Phase

- Diameter

- Barrel diameter: 600 mm

- Type

- Tumble Batch Deflashing Machine

- Condition

- New

- Motor Type

- Electric

- Material

- Mild Steel (MS), Stainless Steel

- Power

- 2 HP

- Voltage

- 415 V

- Dimensions

- 1200 mm x 800 mm x 1200 mm (LxWxH)

- Input Voltage

- 415 V AC

- Rated Current

- 5 A

- Rated Capacity

- 10-50 kg per batch

- Deflashing Media Type

- Plastic pellets or similar

- Control Panel

- Digital Timer and Speed Controller

- Drum Speed

- 8-25 RPM Adjustable

- Finish

- Powder Coated

- Weight

- Approx. 400 kg

- Noise Level

- < 80 dB

- Operation Time Per Batch

- 5-20 minutes

- Safety Feature

- Emergency Stop Button, Interlock Door System

- Mounting Type

- Floor Mounted

About Tumble Batch Deflashing Machine

Tumble Type Batch Deflashing Machine is suitable for batch deflashing of components that can be tumbled without fracture. All important functions are provided on touch screen for ease of operator. After setting up, one click only can start the machine. Such design largely reduce failure rate caused by hand operation and enable it to fulfill automatic upgrade in future.This machine is suitable to deflashing small piece of bakelite products, BMC components, and other plastic goods which are made from brittle plastics. Operator only has to put products on the belt, shut the door, sort out the right parameter, and at last click to start. After finishing, the machine will make an alert ring as it stopped.Features:

- Optimum strength

- High performance

- Excellent functionality

Innovative Deflashing Solution for Rubber and Plastics

This Tumble Batch Deflashing Machine provides an advanced approach for efficiently removing unwanted material from molded rubber and plastic products. Operating at adjustable speeds and using plastic pellets as media, it ensures consistent, high-quality finishes. The drums powder-coated finish enhances longevity, while digital controls offer easy operation and flexibility to meet a variety of deflashing needs across industries.

User-Centric Design with Safety at the Forefront

Equipped with an emergency stop button and an interlock door system, this machine prioritizes operator safety. Its digital timer and speed controller streamline process management while the low noise output (<80 dB) creates a safer and more comfortable work environment. Floor-mounted and robustly constructed, the machine ensures stability during operation, handling even larger loads up to 50 kg per batch.

FAQs of Tumble Batch Deflashing Machine:

Q: How does the Tumble Batch Deflashing Machine improve the deflashing process for rubber and plastic products?

A: The machine automates the removal of excess flash from molded components, using adjustable speeds and plastic pellets to achieve uniform surface finishes. This enhances product quality and reduces manual labor compared to traditional hand deflashing.Q: What types of materials can be processed with this machine?

A: It is designed to deflash a wide range of rubber and plastic products, making it suitable for automotive, industrial, and general manufacturing applications.Q: When should I adjust the drum speed during operation?

A: Drum speed, adjustable from 8 to 25 RPM using the digital control panel, should be set based on the size, material, and flash thickness of the components, as well as the batchs sensitivity to abrasion.Q: Where can this equipment be installed in a manufacturing setup?

A: The machine is floor-mounted and compact, with dimensions of 1200 x 800 x 1200 mm, making it suitable for factory floors in manufacturing or export units.Q: What is the deflashing process using this batch machine?

A: Load components (up to 50 kg) and deflashing media into the drum, set the desired speed and timer on the control panel, then start the process. After 5-20 minutes, the deflashed components are ready for unloading.Q: How user-friendly is the machine in terms of operation and maintenance?

A: A simple digital interface, emergency stop button, and safety interlock system make it easy and safe to operate. The powder-coated, robust steel construction also minimizes maintenance needs while providing long-term durability.Q: What are the key benefits of using this Tumble Batch Deflashing Machine?

A: It increases operational efficiency, ensures consistent product quality, reduces workplace noise, and prioritizes operator safety with its built-in safety features.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Deflashing Machines Category

Indexing Table Type Deflashing Machine

Condition : New

Motor Type : Other, Servo Motor

Power Source : Electric

Automation Grade : Semi Automatic

Type : Indexing Table Type Deflashing Machine

Material : Mild Steel

Rotary Table type Deflashing Machine

Condition : New

Motor Type : Other, Induction Motor

Power Source : Electric

Automation Grade : Automatic

Type : Rotary Table type Deflashing Machine

Material : Highgrade Stainless Steel

Automatic Tunnel Type Continuous Deflashing Machine

Condition : New

Motor Type : Other, Induction Motor

Power Source : Electric

Automation Grade : Automatic

Type : Continuous

Material : Mild Steel

Automatic Tumbling Belt Deflashing Machine

Condition : New

Motor Type : Other, Beltdriven motor

Power Source : Electric

Automation Grade : Automatic

Type : Belt Tumbling Machine

Material : Metal

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS